Destruction and erosion of materials in high-speed flows

|

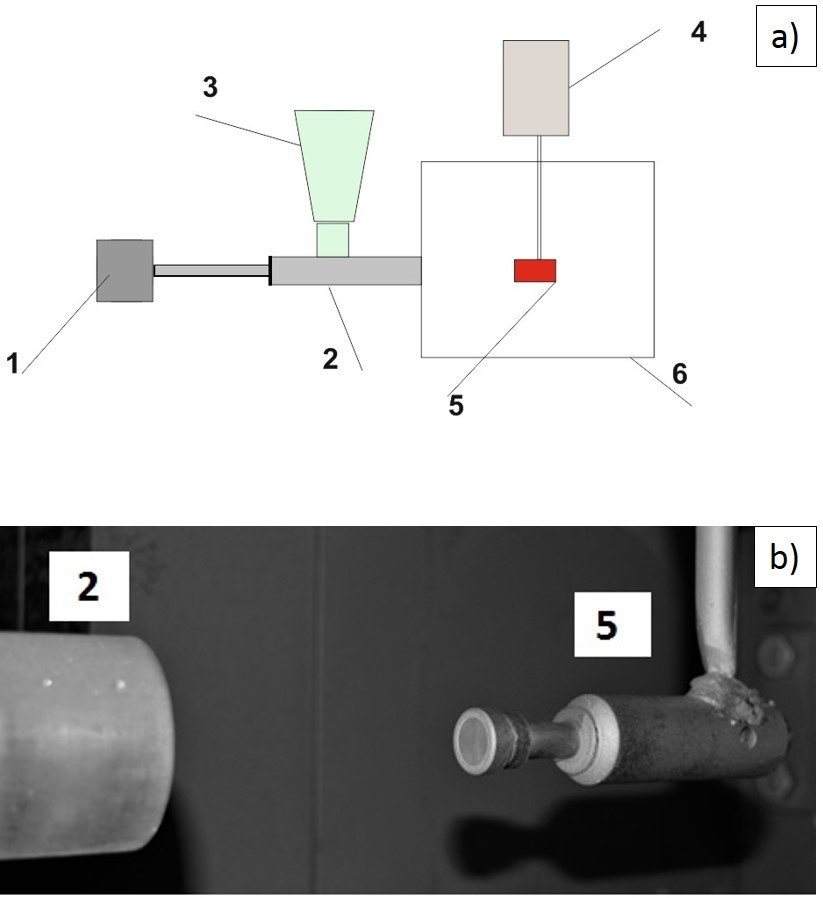

| Figure 1. (a) – scheme of the experimental setup 1 – compressor room, 2 – air flow acceleration pipe, 3 – solid particles feeder device, 4 – sample inlet device, 5 – holder with mounted samples, 6 – working chamber; (b) – working chamber view. |

Solid particle erosion tests are performed in a

modified small-scale wind tunnel. Material samples are tested a two-phase flow

(air mixed with abrasive particles). The abrasive particles were accelerated by

an air flow. The scheme of the utilized experimental setup is shown in figure. The

experimental setup provides the ability to control all key parameters of the

experiments: particle velocity (40 – 300 m/s and more), particle concentration,

and duration of the experiment.

Solid particle erosion inevitably leads to

surface degradation which is also a source of information about material

behavior in conditions of erosion. We register sample mass degradation, surface

roughness change, and carry out microstructural analysis of the samples. This

provides possibility to determine threshold characteristics of the fracture

process.

|  |  |

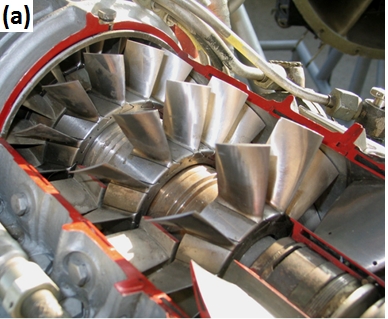

Figure 2. First stage comp of aero-engine axial compressor (PZL-10W). (a), blade (b) and sample after erosion tests (c). | ||